The right

welding gloves can make a significant difference in your welding speed, outcome,

and safety. The key factor for getting a suitable welding glove is finding the

right balance of dexterity and heat protection. Here is some general information

you need to know before choosing the welding gloves that are right for you.

Before you choose a glove, you need to know what type of welding you will be doing. Different techniques have different requirements on the gloves and the protective properties the gloves should have. Here we describe the most common welding techniques.

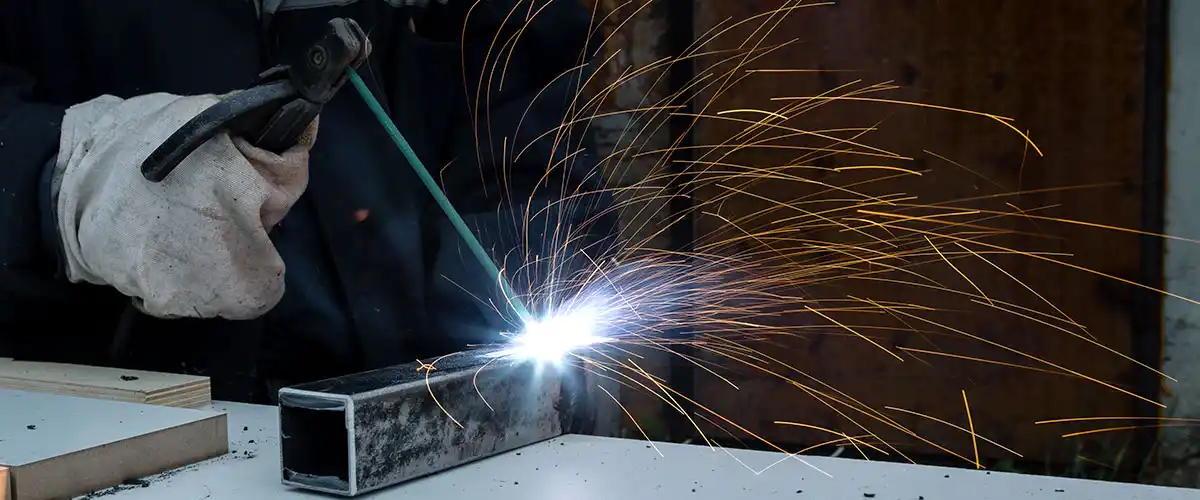

Stick welding

is one of the most popular and is used in the construction of heavy steel

structures. This type of welding uses electricity to melt a metal filler electrode

that melts both the metal joint and electrode all at once. Therefore, it fuses

two pieces of metal together and fills the joint with filler metal at the same

time. Like MIG welding, you will expect high heat and a lot of sparks.

MIG welding

uses electricity to join the metal by forming an arc between the electrode and

the metal. When compared to Tungsten Inert Gas (TIG) welding, this style

of welding is less precise but works well for longer runs. There will be more

sparks flying and splash on our hand. Therefore, it is recommended to wear a

higher heat protection welding glove for this type of welding.

Tungsten Inert

Gas welding is a highly technical style of welding requiring a lot of

precision. It is a process that joins metals by heating them with an arc

between a tungsten electrode (non-consumable) and the workpiece. While it

requires high dexterity to maintain proper control, the type of welding glove

you look out for is going to be different from MIG and stick welding.

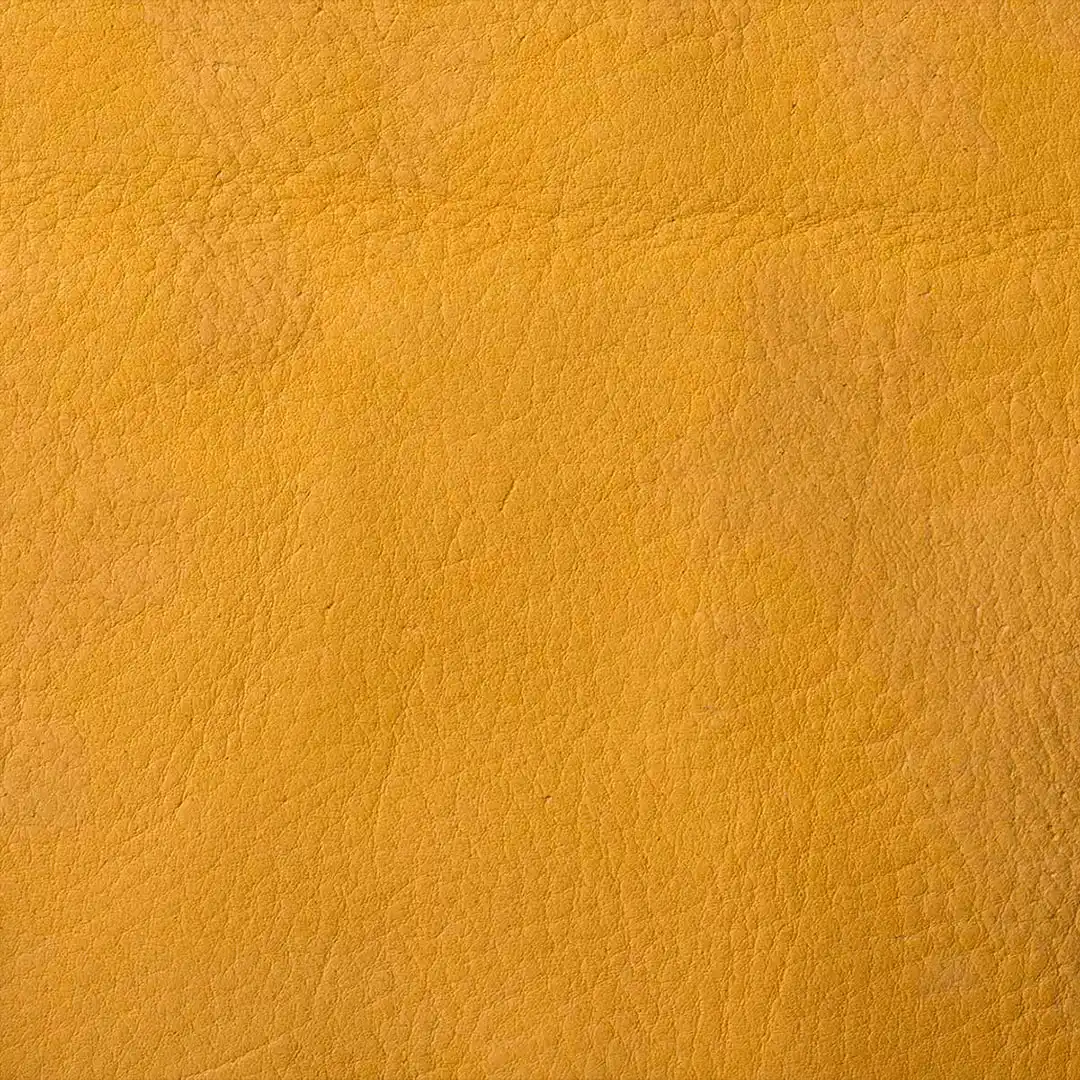

Leather is a natural

material and adapts to the surrounding temperature and environment. It is a durable

and flexible material created by tanning animal rawhide and skin, it is very durable,

non-conductive and dissipates heat well. That’s why it is the most suitable

material for welding protection. But

just like there are options for the type of welding, each leather has its

proper purpose:

Cowhide is the

most popular leather due to its wide range of quality and uses. Durable and

comfortable. Cowhide is typically used in Stick or MIG welding for the highest

level of heat protection.

Goatskin is

another type of leather commonly used as a replacement of cowhide as it offers

great abrasion and tensile strength but remains soft and supple. Unlike

cowhide, goatskin works great for TIG welding. It provides good dexterity and

flexibility.

Tough and

durable yet comfortable, this less-popular leather is preferred for TIG welding

on its excellent dexterity.

A tough hide

that performs well in wet and oily conditions, pigskin is great for TIG, MIG,

and Stick welding but is not recommended for throwin’ around on break.

Deerskin is a

soft, supple hide and provides good feel and nice dexterity because of that

this leather is typically used in TIG welding gloves.

Elkskin won’t

harden as fast as cowhide when exposed to high heat, which means less hand

fatigue. This type of leather is typically used in stick or MIG welding due to

the high heat that is used.

Like other certified

gloves, it is important to make the right choice of gloves for the work you do.

EN12477:2001 + A1:2005 standard is intended

explicitly for gloves designed to be used during welding operations and allied

processes. This standard consists of a combination of EN388, EN407, and

EN420 tests. Welding gloves are required to withstand mechanical risk and heat

resistant risk, particularly to small splashes of molten metal, short exposure

to convective heat, to radiant heat, and to contact heat.

Other than that, EN12477:2001 + A1:2005 standard also assessed according to its design and purpose. It is

clearly defined into two categories:

Type A refers to gloves with higher

protection against heat but with lower flexibility and dexterity

Type B refers to gloves with lower protection

against heat but with greater flexibility and dexterity

The table below showed how the type of

welding glove is determined to refer to the requirements and standard

| Requirement | Standard |

Minimum performance required |

|

| Type A |

Type B | ||

| Abrasion resistance |

EN 388 |

Level 2 |

Level 1 |

| Blade cut resistance |

EN 388 |

Level 1 |

Level 1 |

| Tear resistance |

EN 388 |

Level 2 |

Level 1 |

| Puncture resistance |

EN 388 |

Level 2 |

Level 1 |

| Burning behavior |

EN 407 |

Level 3 |

Level 2 |

| Contact heat resistance |

EN 407 |

Level 1 |

Level 1 |

| Convective heat resistance |

EN 407 |

Level 2 |

- |

| Resistance to small splashes of molten metal |

EN 407 |

Level 3 |

Level 2 |

| Dexterity |

EN 420:1998 |

Level 1 |

Level 4 |

Welding is a specialized work that needs specific requirements,

particularly on heat protection and dexterity. However, you will need to

understand what type of welding work you will be involved in to pick the right

gloves for the task you do. For stick and MIG welding, higher heat protection

is needed to lower the risk of getting heat related injuries. In contrast, TIG

welding requires a higher level of dexterity to complete the task yet maintain a

decent level of heat protection. The EN standard is essential as the test

result guaranteed minimum heat protection. Therefore, you will be able to use

the test result as a reference point to make informed decisions.

Winter working

gloves & EN511

Metalmix -

glove coating guide