Ever since working gloves entered their golden era back in the 90s, knitted working gloves are commonly used by industries such as construction, property maintenance, assembly, automotive, logistics, and many more. Although these gloves can be very different in nature, they all share the same basic components that make a knitted working glove.

Before a knitted glove is made, it starts as fibres, whether natural or synthetic. These fibres are either combed, melted, or engineered into yarns. The yarns are then being fed to a machine that will twist and knit the gloves. The glove shell liner is formed when the knitting process is done.

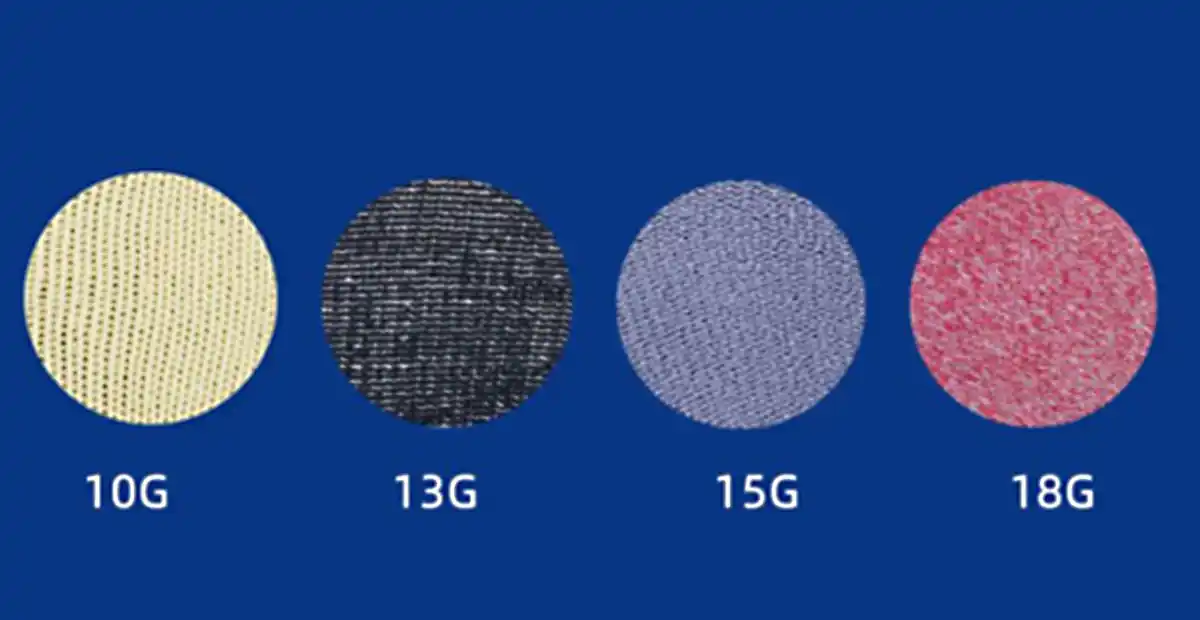

These glove shells are often referred to using the term gauge, for example, a “13-gauge” glove. The term gauge simply refers to the number of stitches per square inch when a knitting machine produces a glove. Traditionally speaking, and depending on the yarn, the higher the gauge, the thinner, and more dexterous the glove can be. The lower the gauge of a glove, the thicker and warmer it can be.

Up next, the glove shell liner will be sent in for a coating process, putting an additional rubber coating to safeguard the most vulnerable part of the hands – the palm. The subject of coating is too big of a topic to cover here. For specific safety requirements, the rubber coating topic is further divided into material, types, and layers. (To read more, click here to learn about rubber coatings)

The glove shell liner makes up the largest component of the gloves. Not only does it serve as a last line of defence to the hand, but the material used to construct the glove determine the wearing experience, primarily dexterity and comfort. Different materials also provide different levels of breathability and durability. Many gloves feature a mixture of materials for the shell, providing added versatility for various functions.

On the whole, most glove shell liner materials are very soft and flexible, thus contribute to fit snugly onto the wearer’s hand. They are also breathable and wicks away moisture better compared to other forms of gloves. As an added benefit, the materials used for knitted gloves are machine washable, which means you can wash the glove instead of throwing it away if it becomes dirty.

The most common shell materials for knitted gloves available with their unique feature are listed below:

Bamboo - is created from the pulp of the bamboo plant. It is both a resilient and durable fibre, which makes it perfect for an outdoor working glove. It also has natural antibacterial and hypoallergenic properties suitable for people with sensitive skin. It reflects 50% more ultraviolet radiation than other materials providing more protection to the skin. Bamboo is also considered a more environmentally friendly fibre due to the harvesting, which requires much fewer resources than other materials.

Cotton - is probably the most comfortable natural fibre you can wear closest to the skin. It has many unique features that are very useful in work gloves. Besides, cotton gloves breathe much better than other materials. They are soft, durable and do not generate static electricity.

Nylon - is a synthetic polyamide fibre. It is a very durable, abrasion-resistant and resilient fibre. Nylon is suitable for outdoor working environments because it is resistant to insects, fungi and mildew. It also has a high moisture-wicking capability.

Polyester - is much like nylon; a common synthetic fibre with high resistance to abrasion, insects, fungi, and mildew, but it’s also resistant to sunlight (UV Rays). Fleece is usually made of polyester shaped to contain a high amount of air and thus provide exceptional thermal insulation properties.

Spandex - is a synthetic, durable fibre made from polyurethane (PU). Spandex has unique elastic properties and can expand up to 600% and spring back without losing integrity. It is also water-resistant, making it suitable for both indoor and outdoor activities.

Dyneema® - is a synthetic fibre, allegedly 15x stronger than steel at the same weight. It excels in cut and abrasion resistance and has a high resistance to chemicals and UV. It is extremely light and still able to have high resistance against deformation.

HPPE - High-performance polyethylene (HPPE) is a mixture of synthetic fibres, specially designed to protect the hands from cuts and abrasions. HPPE is unaffected by moisture (e.g. sweat) or UV radiation. This means it is able to maintain its molecular integrity despite harsh working environments. Suitable for all weather and a variety of industries.

Jonnyma® - is a strong polyethylene fibre with extremely high molecular density. Despite a very lightweight this fiber also keep good ductility under extreme condition such as the presence of UV, chemicals and extreme cold temperatures. Additionally, this fibre has great electrical insulation. Often used in applications such as bulletproof vests, bulletproof glass and in gloves to provide cut protection.

Kevlar™ - is a synthetic aramid fibre. Despite its low weight, it is sturdy, fire-resistant and can endure up to 700°C heat momentarily. Kevlar® can handle a prolonged heat exposure of about 250°C. Kevlar® also provides cut-resistance properties.

Tuffalene® - is an ultra-tough polyethylene fibre used in bulletproof vests, bulletproof glass, and gloves to provide cut protection. This fibre offers bare hand sensitivity, superior dexterity, and good cut-resistance. It is also often used in combination with other materials such as glass fibre, enhancing cut-resistance properties.

When working in cold and windy environments, gloves with thermal insulating properties are preferred. If the temperatures are very low, a winter glove is required to avoid cold hand injuries such as white fingers or frostbite. We highly recommend a glove that is certified against cold according to the EN511 standard for long term exposure.

Knitted gloves with thermal insulating properties come in two variations. It can have a thicker shell liner that is brushed from the inside to create thermal insulation. The other option is an additional inner liner glued or sewn together with the glove shell. In some cases, it is both glued and stitched to give enhanced durability. Either way, knitted insulating gloves trap air to maintain the body warmth from the hands and prevent heat from dissipating. The result is significantly warmer gloves.

Below are some common materials used for thermal insulation.

Acrylic – is a synthetic fibre made from a polymer (polyacrylonitrile). It is very durable, wicks away moisture. As a material designed to mimic natural wool, acrylic is soft, warm, and lightweight.

Fleece - Fleece is usually made of polyester which has been spun to trap large amounts of air and thus provide exceptional thermal insulation properties. It is a very light material and also has excellent moisture resistance.

Thinsulate™ - is an insulating material based on microfibres less than one-tenth of the width of a strand of hair and thereby captures the significant amount of air in the material, leading to high thermal insulation while keeping the liner thin. The insulation is soft, flexible and keeps the hands warm even when exposed to wind and water.

Knitted gloves provide comfort and a better fit than most other types of gloves. The reason is that the glove liner is knitted using a single thread resulting in a seamless glove in a literal sense. Additionally, the knitting technique makes the glove fabric extremely stretchy without deformation. The stretch can, in most cases, allow the user to choose a smaller than usual sized glove and still wear it with a very snug fit. These properties result in a wearing experience usually reserved for premium cut and sewn gloves. As always, we recommend doing real-life application tests to find the glove that suits your situation the best.

Ultimately, we have only one pair of hands, and our goal is for you to keep them safe at all times.

When do you need to replace your gloves?

Guide to coatings on knitted gloves