Safety gloves come in many styles and features, different from each other. However, sometimes gloves may look similar to each other, although they are very different. One example of this is disposable rubber gloves and reusable rubber gloves.

The gloves may look quite similar on the outside as both types are made from natural or synthetic rubber. They also share one very important feature, which is a certain degree of chemical protection. This might be less important for household use since household chemicals are generally less harmful. On the other hand, for industrial use with exposure to dangerous chemicals, it´s vital to know the level of protection the gloves give.

Additionally, there are a few key differences which are explained below:

Reusable rubber gloves are thicker (in our range from 0.33mm to 0.7mm)and more comfortable and durable than disposable gloves.

Disposable gloves, on the other hand, are thinner (around 0.1mm), making them highly flexible and more suitable for precision jobs.

Both glove types might have the same glove material, but thicker gloves give higher chemical resistance since more time is needed for a chemical to penetrate the glove. A thicker glove also means it’s more durable and will last longer in normal cases. The thickness is arguably the most important property when looking at the chemical protection properties of the gloves.

Reusable rubber gloves are usually non-ambidextrous, which means they always come with a left hand and right hand in a pair.

Disposable gloves are ambidextrous and can be used for both the left hand and the right hand.

That´s why reusable rubber gloves are packed & sold in a pair, while disposable gloves are packed in a box. The box will state how many

pieces of gloves are inside (not pairs).

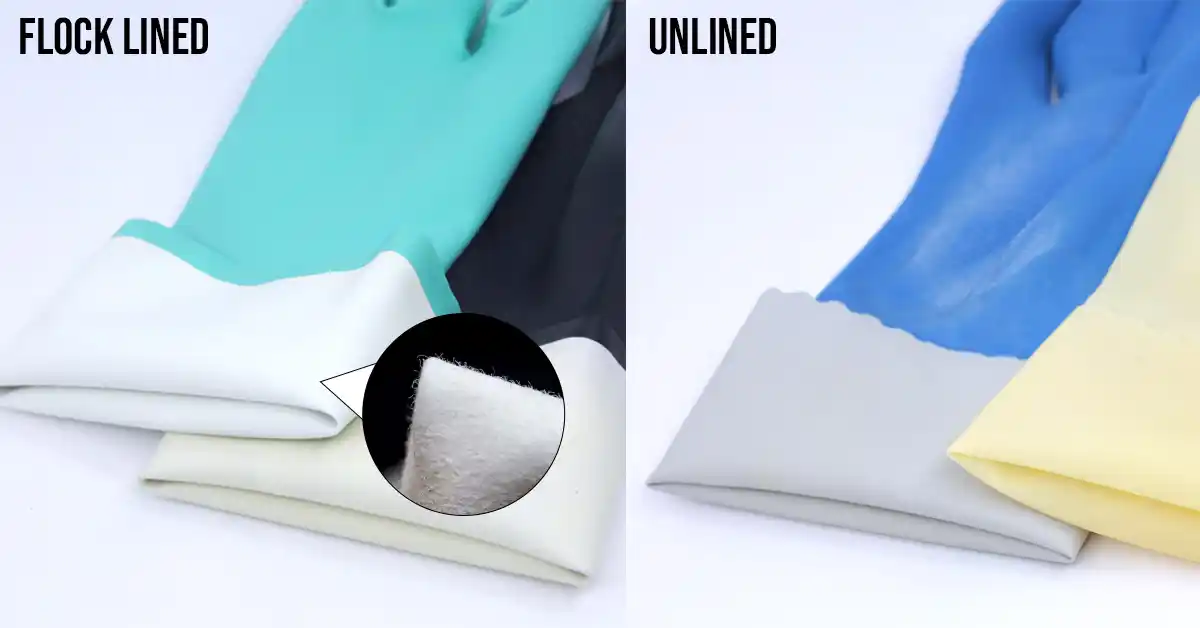

Reusable gloves are often flock lined because they are designed for wearing over extended periods of time. Flock lining is when the inside of the glove is sprayed with cotton flock to create a thin cotton layer that provides comfort to the user. Those with sweaty hands will find it helpful as the cotton flock provides good absorption and increase comfort by keeping the hands dry.

Disposable gloves are unlined, which is partly what helps keep them so thin. A glove with no inner liner usually undergoes chlorination to provide a smooth donning experience. Since there is no cotton flock in the inner lining of unlined gloves, it greatly reduces the risk of flock contamination, which is particularly important in the food industry.

Reusable gloves are designed for prolonged wearing, generally used for house chores such as dishwashing and cleaning, or industrial use, such as janitorial cleaning, general maintenance, painting etc. For chemical protection from aggressive chemicals, this is the safest type of glove since the material is thicker.

Disposable gloves are more commonly used in the medical industry, food industry, dental clinics, tattoo industry, beauty and hair salons, etc. These are all industries where workers are required to change their gloves often to prevent cross-contamination.

| Type of gloves | Reusable gloves | Disposable gloves |

| Characteristics | Thicker, comfortable, durable | Thin, high flexibility, high precision |

| Ambidextrous & packaging | Specific left & right hand, sold in pairs | Fits both the left & right hand, sold in boxes |

| Inner liner | Flock lined | Unlined |

| Usage areas (example) | Heavy duty, chemical industries, painting, house chores, etc | Medical, dental, hair salon, tatoo, workshop, house chores, etc |

Both reusable and disposable gloves have their unique properties, although they share some similarities. Because of this, it is important to know the advantages and shortcomings of each type of glove. Disposable gloves are the best fit for any work that requires high precision or high cleanliness, whereas reusable gloves would be a better choice in durability, comfort, and if chemical protection is needed.

With knowledge and the right information, it’s easier to pick the right glove for the right application. If you have specific questions about chemical risks at your job and what gloves to choose, remember to ask your safety officer, who should be able to provide you with an answer using the company risk analysis.

Guide for cut-resistant gloves

Size guide